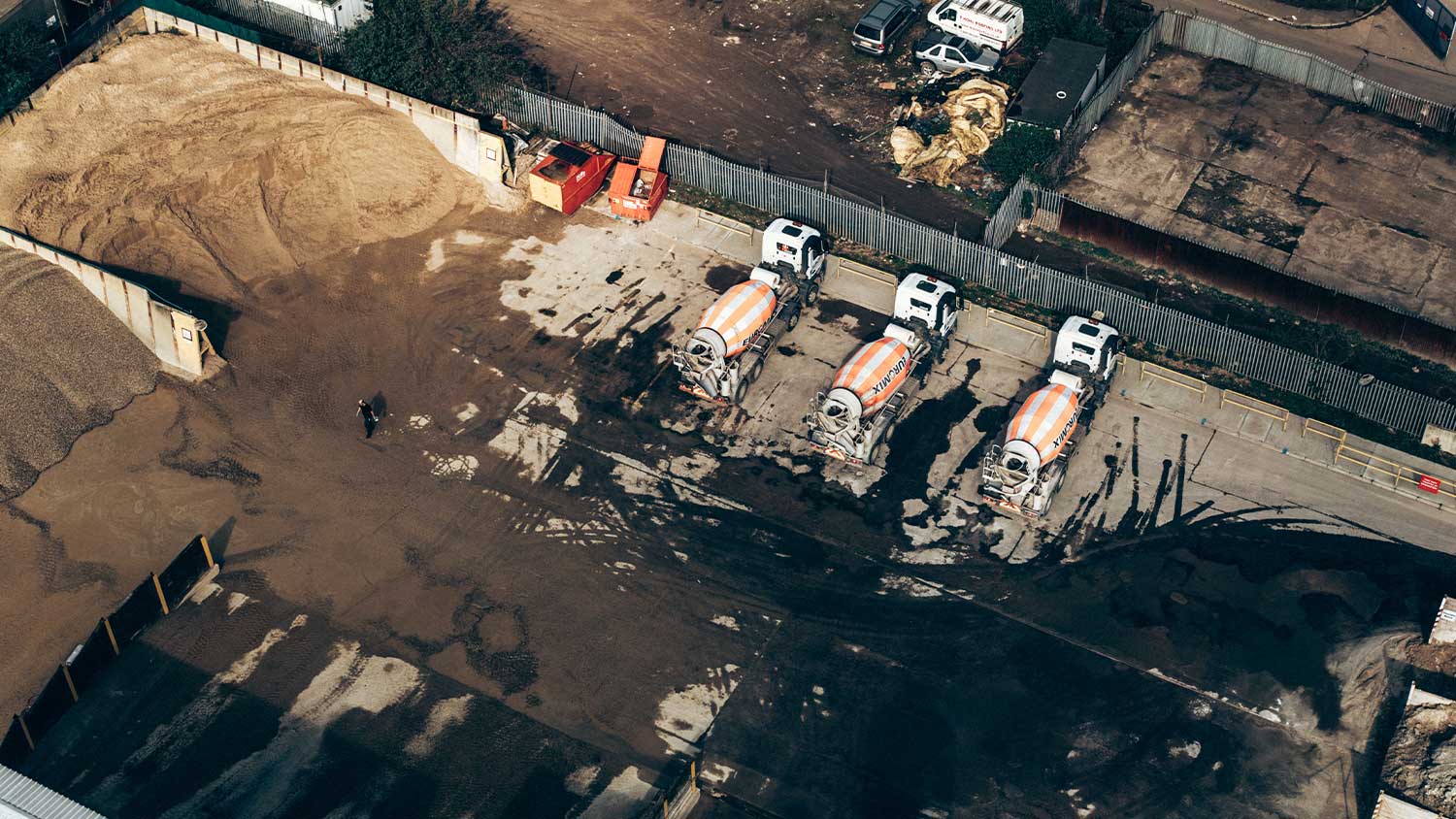

Whether you’re a first-week apprentice on a residential job site or a seasoned veteran working on a large-scale commercial oil well, chances are you’re not far from cement slurry on any given day.

One of the most versatile and widely-used materials in construction, cement slurry often quite literally carries the team. However, there’s more to this quiet achiever than meets the eye.

With a massive range of chemical additives to alter the mixture, a long list of potential job applications, and a few real dangers to the environment if not managed correctly, it’s worth taking a closer look at cement slurry to use it safely and effectively.

In this article, we outline what cement slurry is, what it’s made of, what it’s used for and what to know about correct slurry disposal and washout.

What is Cement Slurry and What is it Made Of?

Cement slurry is a pourable liquid mixture of cement, chemical additives and water. Most often grey in colour, slurries are used across multiple industries for a range of applications, from commercial oil wells to residential driveways.

The name slurry is sometimes used interchangeably with grout, blended cement, mortar, controlled low-strength material (CLSM) and flowable fill, however, these comparisons are not always accurate.

Slurries do come in many forms and be altered to suit different purposes, whether that’s through adding weighting agents, fluid-loss control agents, retarders and more, but must always be pourable. For example, cement slurries used in drilling industries like oil and gas often have a thinner consistency so they can easily disperse over irregular surfaces.

In residential construction on the other hand, the slurry mixture may be thicker, with a focus on creating a strong and water-resistant foundation for building.

Is Cement Slurry Different to Mortar?

Unless you’re an experienced wet trade contractor, it can be easy to be confused by the many terms relating to different material mixtures. Just like the difference between “cement” and “concrete”, some people often confuse the terms “slurry” and “mortar”.

By definition, cement slurry is pourable. Cement mortar is a thicker paste-like mixture of bonding agents and fine aggregates like sand, water and lime. In masonry, mortar is used to bind bricks and blocks.

What is Cement Slurry Used For?

Cement slurry is a versatile building material and can be used for a wide range of purposes, depending on the chemical additives used in the mixture. In residential construction, cement slurry is often used for:

- Concrete slabs

- Concrete foundations

- Driveways

- Concrete repairs

- Brickwork

- Casting

- Plastering

- Flooring

Common commercial applications for cement slurry include:

- In oil wells as temporary plugs

- Road repairs

- Building foundations

Is Cement Slurry Bad for the Environment?

Cement slurry waste can be damaging to the environment if washout is not managed correctly. Common environmental impacts of cement slurry include damage to vegetation and animal life caused by hosing down tools or barrows emptied into surrounding garden beds or onto lawns after washout.

In fact, the chemical additives used in slurry mixtures can alter the chemical composition of soil and even seep into groundwater, increasing PH levels.

How Should You Manage Leftover Cement Slurry?

In Australia, the Environment Protection Authority (EPA) has the power to impose harsh fines on contractors who pollute the environment due to improper slurry disposal.

These fines fall under illegal dumping in the Protection of the Environment Operations Act 1997 (POEO Act), which includes on the spot fines up to $7,500 for individuals and $15,000 for corporations, with additional fines if the waste is causing damage to waterways.

So how should you manage leftover cement slurry and washout of tools?

Proper Cement Slurry Disposal With SLURRYTUB

We’ve seen decades of substandard slurry management on job sites, and also saw the need for tools that were fast and effective to use. That’s why we created SLURRYTUB, an innovative filtering system to capture and filter cement slurry into visibly clear water, ready for recycling.

SLURRYTUB’s heavy-duty recycled plastic tub provides sturdy access for wheelbarrows, with a biodegradable filter liner to turn previously harmful slurry into usable recycled water. When the mixture has dried, you can dispose of the hardened waste and the biodegradable filter into the skip.

To learn how you can create a safer, cleaner and more environmentally friendly worksite with SLURRYTUB, get your first Starter Kit today.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.